But it's so fun. Since nothing seems to be being done about the fud, might as well play along.Don't bite to bullshit.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Playstation 5 [PS5] [Release November 12 2020]

- Thread starter BRiT

- Start date

It's not fun. it's a method to repost continuously the same FUD which derails the honest discussions: Inserting a BS claim in every post until someone bites and ask where it's from, then he repost the twitter crap, then others reply to keep it here, then someone says it's BS and there's no source. Wait a day, rinse, repeat.But it's so fun. Since nothing seems to be being done about the fud, might as well play along.

When you put it that way, yeah, I guess I'm not helping.It's not fun. it's a method to repost continuously the same FUD which derails the honest discussions: Inserting a BS claim in every post until someone bites and ask where it's from, then he repost the twitter crap, then others reply to keep it here, then someone says it's BS and there's no source. Wait a day, rinse, repeat.

I was going to reply to the DS5 thread, but this is more applicable to the overall console, so I'll ask it here.

Do you think Sony will have their own Voice Assistant or will they merely pair with Google or Alexa? Will their voice assistant process most commands locally or will they have a two tier feature where more complex commands will be sent to 'the cloud' for additional processing?

Do you think Sony will have their own Voice Assistant or will they merely pair with Google or Alexa? Will their voice assistant process most commands locally or will they have a two tier feature where more complex commands will be sent to 'the cloud' for additional processing?

Sony have a history of wanting features to work offline as much as possible unless it's an obvious social or network related feature. The current voice commands are local only. This assistant however seems to be more based on community and network provided help, so it might process the sound locally but gets the help data from the net. If they send any actual waveform to a server it will need to be clearly indicated in the privacy policy, and a checkbox to disable it in the privacy menu.I was going to reply to the DS5 thread, but this is more applicable to the overall console, so I'll ask it here.

Do you think Sony will have their own Voice Assistant or will they merely pair with Google or Alexa? Will their voice assistant process most commands locally or will they have a two tier feature where more complex commands will be sent to 'the cloud' for additional processing?

This can of worms would need clear information like this:

https://store.google.com/category/google_nest_privacy

Yes, I expect it to have an opt-in process, I didn't even consider that they wouldn't make it a user option. That's just the way everything seems to be today. It should be fairly standard boiler-plate privacy disclosure and options, considering the push around this in 2018 (perhaps earlier, perhaps later?).

Though I do believe that Microsoft has made the move to not use their own assistants on their consumer products, and will just continue their partnerships with Google and Amazon. I don't know if they could/would ever work out integrations with Apple.

Though I do believe that Microsoft has made the move to not use their own assistants on their consumer products, and will just continue their partnerships with Google and Amazon. I don't know if they could/would ever work out integrations with Apple.

I feel that design oversight is perhaps too strong a phrase to use, it comes across as incompetence or just plain ignorance, which at times could be the case, but not necessarily always the case.Thats not wrong @iroboto ...but i like to think that risks like that, while both a factor for sony and ms, have clearly been thought through to some extent regarding longevity.

Having an rrod level disaster like 360 or disc read error disaster like ps1ps2 isnt unlikely but its also not something i see sony or ms blatantly overlooking in their design if people online can easily call it out as a problem only a year or two after launch.

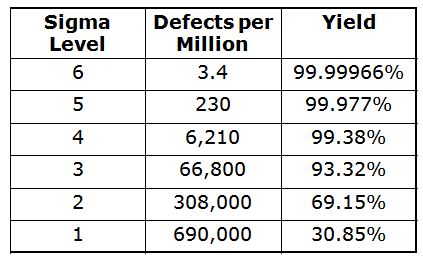

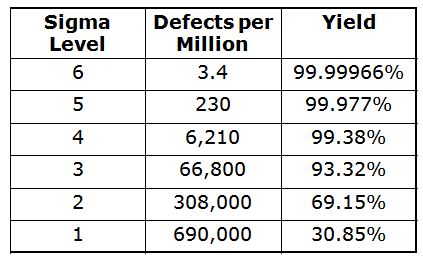

When it comes to manufacturing, there is always a discussion about yields and defects. This is for any product. If we look at a screw, a defect might be that the dimensions are not to spec, something simple like that. Or a bolt not be exactly to spec. We have a way to define this in manufacturing which is often categorized under sigma levels. And they look like the below chart.

So at 6 sigma, you're only getting 3.4 defects per 1 million parts. Or in the case of screws, you're only getting 3.4 defective screws per 1 million. Different industries have different tolerance levels, something like Home Depot can absorb more defects per million as they sell to the home consumer and the need to have insanely specc'd parts is relative close to 0. But if you're building rockets and airplanes, a defect on a fastener could cause the plane to crash. That being said, by increasing the sigma level we also dramatically increase the cost levels. (rockets and airplanes require much higher sigma values than 6 for instance)

The reason why I'm talking about sigma levels is because at the end of the day, both companies have a price point they need to hit. Anything that can remove costs but keep the device working is likely what's going into play here to maximize its price/value curve in consumer eyes. So it may not be a design decision, necessarily that may be the cause of failure, the design may work very well, but a defect may cause the whole system to crash.

So when we look at x360 RROD for instance, I think x360 was closer to 1 sigma in this case? I don't recall, sounds like it was worse than this to be honest. But the oversight was not the design, it was the solder!

The industry demanded lead free solder to be safer around humans, and this change resulted in a way their design did not compensate for. Which is they heat output of the console. The lead free solder is not as flexible as leaded solder, and the heat would cause the board to flex over time eventually resulting in the connections in the solder cracking and thus a loose/empty connection would cause RROD.

There was no method for them to get around lead free soldering as this was law, so they quickly made as many revisions as possible to find newer cooling methods to bring the temperatures of the board down to cease the flex from occurring.

In some sense, one person might look at this as, well, it's a design flaw, it was too hot for the lead free solder that they didn't account for. And that's perfectly valid reasoning. But MS and Sony don't manufacturer all of their parts, many of them are sourced as well. You aren't necessarily privvy to all the sigma values for all the parts your're sourcing for. You may have chosen to make a design with some parts that are say 2 sigma vs an equivalent part that is 4 sigma or greater, thinking it wouldn't have an adverse affect on your console (to save costs). But in the end that 2 sigma choice may come back and haunt you, at a rate of 300K per million defects. And those defects if part of a critical chain snowball into absolute failure after pro-longed periods of play time.

And that's hard to ask a manufacturer to test. To heat test 1 million units for 6 years straight to see if it will last. They have some data from server usage, but those are likely much higher sigma devices. We pay the big bucks for server equipment for a reason. And Sony and MS have their own proprietary cooling solutions, which we don't know how well they will perform after years of service either. So there are more unknowns. But at the end of the day choices need to be made with incomplete data, and price points need to be met meaning we can't choose 6 sigma parts across the board.

So I don't necessarily believe it's bad design, but a freak chance that something you chose to cheap out on (or in the case of 360, something changed), turned out to have dramatic impacts on your overall system resulting in failure.

You know, with all of these exotic features that PS5 has, I hope launch units come with a demo disc like the first Playstation did. The one with the sting ray and t-rex on it, but this time, have it show off the 3D sound and tactile features. And yes, I want a disc. And I want it to be black on the bottom.

Sony are generally quite good at providing demos of features, just look at PSVR

Poorly made in china is great book about manufacturing issues. Probably has nothing to do with console issues. Anyway, it's completely possible to have a perfect design but during manufacturing something gives. Like someone optimizes cost(cheaper materials, cheaper way to put things together, doing something too fast to optimize throughput,...) without buyer knowing it until quality defects become very obvious. And hence we enter testing to try to enforce some minimum bar.

This is such a great book and a good read: https://www.amazon.com/dp/B004G5Z2A8/ref=dp-kindle-redirect?_encoding=UTF8&btkr=1

This is such a great book and a good read: https://www.amazon.com/dp/B004G5Z2A8/ref=dp-kindle-redirect?_encoding=UTF8&btkr=1

I've made the same argument in the Coronavirus discussion. Simple people think governments should have acted differently, but they acted correctly the info available. The info just wasn't up-to-date enough because the virus was new and untested. Same with super-fast SSD storage - they can only design based on best guesses derived from current understanding. Those guesses may be wrong, but there's nothing that can be done about that.So I don't necessarily believe it's bad design, but a freak chance that something you chose to cheap out on (or in the case of 360, something changed), turned out to have dramatic impacts on your overall system resulting in failure.

Yea. Without getting political about it; I am generally okay with businesses using data to figure things out; removal of the optical port for instance; sometimes they are wrong. With governments and where lives matter, no one wants to be reduced to a financial cost you know lol. But yea, like the tsunami in japan that caused Fukushima, they knew they did not have a sea wall that could survive that magnitude of earthquake; but they kept putting it off because they wanted to use the funds elsewhere. In the end, it came. And they have a permanent nuclear disaster zone there for generations of humans to come.I've made the same argument in the Coronavirus discussion. Simple people think governments should have acted differently, but they acted correctly the info available. The info just wasn't up-to-date enough because the virus was new and untested. Same with super-fast SSD storage - they can only design based on best guesses derived from current understanding. Those guesses may be wrong, but there's nothing that can be done about that.

It’s all very hard to say, it’s not justification for anything I guess, sometimes you just didn’t know or could not know. And sometimes we do know, and they know but chose to make profits instead.

See the fight against leaded gas, See climate change data back to the 1980s and before that. See any sort of environmental hazard that people live through. Flint Michigan, etc.

Where the data points towards a need for action but people don't act, that's bad decision making. Where the data doesn't point to a course of action that's needed, that's no-one's fault. There's a difference between being cautious and being paranoid. Moving tech forwards generally means taking risks. If one of these companies went with an SSD and the other didn't for fear it might burn out, not trusting that the tech was proven yet, the SSD-choice would completely win that side of the fight, even if years later that company pays the price in service costs. SSDs (and flash storage) are an essential part of 'next-gen' tech that's up and running quickly, from PCs to phones to TV boxes. A console coming out with 5 minute load times will look archaic next to a rival loading in seconds. They both have had to jump in feet first. We'll see how that pans out in three+ years' time.

Leadfree solders are very reliable today, one problem remains the lack of expertise in the field. Americans were late at this, and the expertise is still much less developed than other countries who were planning to get rid of Sn-Pb. I remember some astroturf campaign trying to convince people that the toxicity of lead was a hoax, but the law passed anyway. Even today there are people who honestly think the toxicity is a hoax.I feel that design oversight is perhaps too strong a phrase to use, it comes across as incompetence or just plain ignorance, which at times could be the case, but not necessarily always the case.

When it comes to manufacturing, there is always a discussion about yields and defects. This is for any product. If we look at a screw, a defect might be that the dimensions are not to spec, something simple like that. Or a bolt not be exactly to spec. We have a way to define this in manufacturing which is often categorized under sigma levels. And they look like the below chart.

So at 6 sigma, you're only getting 3.4 defects per 1 million parts. Or in the case of screws, you're only getting 3.4 defective screws per 1 million. Different industries have different tolerance levels, something like Home Depot can absorb more defects per million as they sell to the home consumer and the need to have insanely specc'd parts is relative close to 0. But if you're building rockets and airplanes, a defect on a fastener could cause the plane to crash. That being said, by increasing the sigma level we also dramatically increase the cost levels. (rockets and airplanes require much higher sigma values than 6 for instance)

The reason why I'm talking about sigma levels is because at the end of the day, both companies have a price point they need to hit. Anything that can remove costs but keep the device working is likely what's going into play here to maximize its price/value curve in consumer eyes. So it may not be a design decision, necessarily that may be the cause of failure, the design may work very well, but a defect may cause the whole system to crash.

So when we look at x360 RROD for instance, I think x360 was closer to 1 sigma in this case? I don't recall, sounds like it was worse than this to be honest. But the oversight was not the design, it was the solder!

The industry demanded lead free solder to be safer around humans, and this change resulted in a way their design did not compensate for. Which is they heat output of the console. The lead free solder is not as flexible as leaded solder, and the heat would cause the board to flex over time eventually resulting in the connections in the solder cracking and thus a loose/empty connection would cause RROD.

There was no method for them to get around lead free soldering as this was law, so they quickly made as many revisions as possible to find newer cooling methods to bring the temperatures of the board down to cease the flex from occurring.

In some sense, one person might look at this as, well, it's a design flaw, it was too hot for the lead free solder that they didn't account for. And that's perfectly valid reasoning. But MS and Sony don't manufacturer all of their parts, many of them are sourced as well. You aren't necessarily privvy to all the sigma values for all the parts your're sourcing for. You may have chosen to make a design with some parts that are say 2 sigma vs an equivalent part that is 4 sigma or greater, thinking it wouldn't have an adverse affect on your console (to save costs). But in the end that 2 sigma choice may come back and haunt you, at a rate of 300K per million defects. And those defects if part of a critical chain snowball into absolute failure after pro-longed periods of play time.

And that's hard to ask a manufacturer to test. To heat test 1 million units for 6 years straight to see if it will last. They have some data from server usage, but those are likely much higher sigma devices. We pay the big bucks for server equipment for a reason. And Sony and MS have their own proprietary cooling solutions, which we don't know how well they will perform after years of service either. So there are more unknowns. But at the end of the day choices need to be made with incomplete data, and price points need to be met meaning we can't choose 6 sigma parts across the board.

So I don't necessarily believe it's bad design, but a freak chance that something you chose to cheap out on (or in the case of 360, something changed), turned out to have dramatic impacts on your overall system resulting in failure.

From what I remember some manufacturers, specially japanese, moved very quickly to SN100C which is very similar to Sn-Pb in mechanical properties, but a higher temperature profile. The rest seem to have decided to standardize on SAC305 with is brittle (silver content), I don't know why, probably the temperature, or availability, or some other desirable property.

RoHS was known to be in the works for a long time, it was fully written in 2002, and passed in Feb 2003, maybe MS thought it wouldn't pass? They knew 3 years in advance.

The 360 was still filled with design flaws, it was very well known that silver content in alloys causes the solder to be both stronger and more brittle. The elongation specs of the solder they used was well documented, they decided to take a chance and launch anyway. The borderline thermal design, the borderline mechanical stress, would also have a high failure rate on Sn-Pb, just in smaller numbers.

MS also had a problem using solder joints as mechanical support on the original xbox, which was a fire hazard:

https://www.theregister.co.uk/2005/03/19/xbox_recall_nofix/

The connector was literally supported just by it's solder joint, and instead of fixing the dangerous connector they sent a power cord with an integrated e-fuse. So it seems that MS engineers of that era didn't pay any close attention to solder joint stress, neither in the original XB, nor the 360.

Yea, that's cheap shitLeadfree solders are very reliable today, one problem remains the lack of expertise in the field. Americans were late at this, and the expertise is still much less developed than other countries who were planning to get rid of Sn-Pb. I remember some astroturf campaign trying to convince people that the toxicity of lead was a hoax, but the law passed anyway. Even today there are people who honestly think the toxicity is a hoax.

From what I remember some manufacturers, specially japanese, moved very quickly to SN100C which is very similar to Sn-Pb in mechanical properties, but a higher temperature profile. The rest seem to have decided to standardize on SAC305 with is brittle (silver content), I don't know why, probably the temperature, or availability, or some other desirable property.

RoHS was known to be in the works for a long time, it was fully written in 2002, and passed in Feb 2003, maybe MS thought it wouldn't pass? They knew 3 years in advance.

The 360 was still filled with design flaws, it was very well known that silver content in alloys causes the solder to be both stronger and more brittle. The elongation specs of the solder they used was well documented, they decided to take a chance and launch anyway. The borderline thermal design, the borderline mechanical stress, would also have a high failure rate on Sn-Pb, just in smaller numbers.

MS also had a problem using solder joints as mechanical support on the original xbox, which was a fire hazard:

https://www.theregister.co.uk/2005/03/19/xbox_recall_nofix/

The connector was literally supported just by it's solder joint, and instead of fixing the dangerous connector they sent a power cord with an integrated e-fuse. So it seems that MS engineers of that era didn't pay any close attention to solder joint stress, neither in the original XB, nor the 360.

They are trying to get away with the most amount of power for the cheapest box possible.

And while looking back we'd scoff at it. No one would want to pay a higher price either. People seem to be scoffing at 9.2 TF, for instance. People want more for their money and that means making concessions somewhere.

The best engineering is about accomplishing the design goals for the least amount of money... but when you design, say, medical equipment, the robustness is a bit higher in the design goals than a game console.Yea, that's cheap shit

They are trying to get away with the most amount of power for the cheapest box possible.

And while looking back we'd scoff at it. No one would want to pay a higher price either. People seem to be scoffing at 9.2 TF, for instance. People want more for their money and that means making concessions somewhere.

The original PS1 had plastic rails on the CD pickup assembly, because they saved 5 cents.

yikes lolThe original PS1 had plastic rails on the CD pickup assembly, because they saved 5 cents.

TIL

Miniature Kaiju

Newcomer

The original PS1 had plastic rails on the CD pickup assembly, because they saved 5 cents.

The very same rails that would bend and deform under heat, making it so the system would fail to read discs in certain orientations. Hence how you got some PS1s sitting sideways

Inuhanyou

Veteran

The very same rails that would bend and deform under heat, making it so the system would fail to read discs in certain orientations. Hence how you got some PS1s sitting sideways

So thats why...

The very same rails that would bend and deform under heat, making it so the system would fail to read discs in certain orientations. Hence how you got some PS1s sitting sideways

Upside down, rather! [emoji23]

Similar threads

- Sticky

- Replies

- 71

- Views

- 31K

- Replies

- 126

- Views

- 48K