AMD

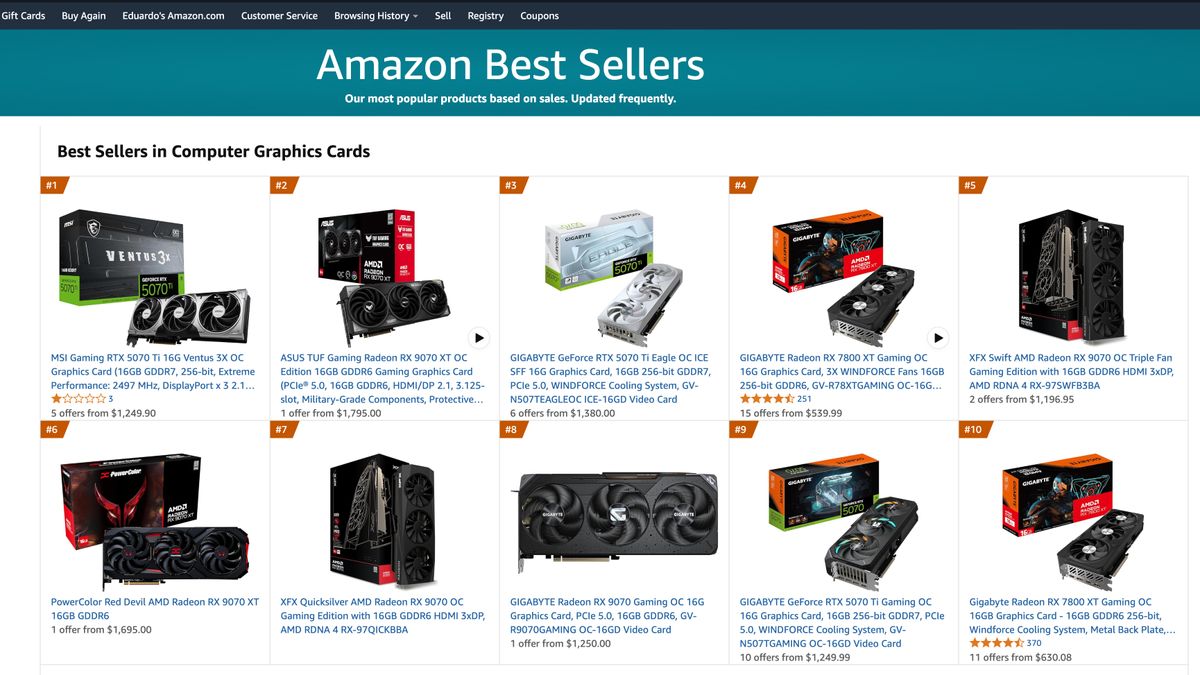

RX 9070 and RX 9070 XT GPUs, which rival the

best graphics cards, were launched on March 5, three days ago. The RDNA 4-powered graphics card is the second best-selling GPU on

Amazon and has taken the first spot in Amazon Germany and Amazon UK. Remember that these standings are dynamic and are subject to change as consumers purchase more units of one graphics card than the other.

Despite the

supply issues with the

GeForce RTX 50-series GPUs, the

RTX 5070 Ti has remained on top of Amazon's best-selling list. The

MSI GeForce RTX 5070 Ti 16G Ventus 3X OC, launched at $829.99, appears to be the most popular model. The

Asus TUF Gaming Radeon RX 9070 XT OC Edition is in second place.

Amazon Germany lists the

XFX Swift Radeon RX 9070 OC White as its best-selling GPU, despite being listed for €929.99 — this is way above its $549 MSRP (around €506), even if you include taxes. On the other hand, the U.K.’s top bestseller is the

Gigabyte Radeon RX 9070 XT Gaming OC, which is already unavailable at the time of this article.

Despite seemingly launching with more stock than Nvidia and Intel, AMD’s RX 9070 series GPUs quickly ran out within a few hours of its launch. Scalpers are now selling them for

more than twice the MSRP, and it’s apparent that people still buy these mid-range cards despite scalpers selling them at high-end prices.

www.tweaktown.com