There are three different things brought up:

1. Efficiency of mobile power plants versus huge, stationary ones.

Well, for starters, those power plants don't pay large fuel taxes. But disregarding that, size is everything in efficiency.

And you would want that electricity to recharge your car at night, when some of those plants are simply throwing away generated electricity, because that's cheaper than turning them off and back on, and prevents brownouts.

2. The difference between an ICE used for driving the wheels or a generator.

You want to prevent any direct, mechanical connection between the wheels and that ICE, if you care about efficiency. Use it to drive a generator, and it becomes so much more efficient, that the losses incurred by charging the batteries and using those to drive (a DC/AC converter and) an electric motor still makes it more efficient overall.

3. The differences between different types of electric motors to power the wheels, or to generate electricity.

Well, for starters, an electric motor only uses electricity when delivering torque, in a very linear fashion. While an ICE burns power all the time, even when idling. And even during acceleration the electric engine is better, simply because it has a higher efficiency (about 300%) to start with.

Which makes sense if you think about it: the combustion is a messy, chemical process, that reacts to all the forces working on it, and has a strict, optimal combustion speed for each of those combinations incurred by driving the wheels directly.

Good luck making that somewhat efficient if you cannot control those forces!

As to why some electric motors make better or worse generators (or motors!):

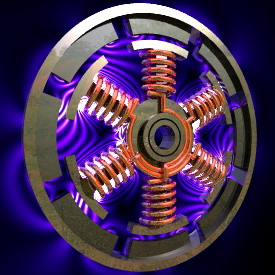

An AC induction motor (the simplest, cheapest and most common one):

Cheap, simple, light, reliable, good torque; what is not to like? It's your basic, cheap workhorse. Not as efficient as brushless or synchronous motors, but still pretty good and much cheaper.

But, as you can see in the animation, there are no magnets or coils on the rotor. So, if you crank it around by braking, not much happens. Because it only works when the coils are inducting a current into the rotor. And for a generator, you want the reverse: you want the rotor to power those coils, not the other way around.

A DC motor:

As there are electromagnets on the outside, it does generate electricity readily.

But the whole design isn't all that efficient for either generating torque or electricity to begin with. The brushes create friction and have overlap, and there's only a few angles where maximum magnetic repulsion is created. Much of the time, it's either powered wrong or pushing in a less than optimal vector.

Strangely enough, they're actually better in generating electricity than converting it to torque, if you want speed control. Because that requires either voltage control (max. efficiency of around 80%), or PWM, which reduces the maximum torque significantly.

Their main benefit is that they're very simple and very cheap. But they're not used if you want efficiency and high torque from low rpm. Like, in a commercial-grade car.

A brushless motor:

Well, they're like an AC motor that you can operate by PWM: no DC/AC conversion needed. And, as they do use permanent magnets, they do produce electricity.

Interestingly enough, they're generally short and wide, while the housing rotates. And because they can deliver very high torque at any rpm, that makes them excellent hub- and brake replacements. They're potentially the best at both driving and generating, when you power them from batteries.

But all the magic is in the electronics and timing. Losses are unavoidable, and the electronics are outright bulky and expensive, compared to the other types. Especially when you want to use them as generators as well.

And the electronics are far more expensive than the motors.

That leaves AC synchronous motors:

If you want efficient, look no further. This is the industry standard, and has been for about a century by now. But they are designed for a single voltage and frequency, which is a problem. Unless you use DC/AC converters and can generate the voltage and frequency you need. But that does incur conversion losses.

In the animation, the rotor uses permanent magnets, which work fine for generating electricity. But the best ones use coils on both the rotor and strator.

Simply because you cannot regulate permanent magnets. They function best at the design spec, and worse at every other speed and power usage.

So, that's why you would want a combination of the brushless and synchronous motor, for the best results.