https://seekingalpha.com/article/4513009-applied-materials-smic-move-another-headwind

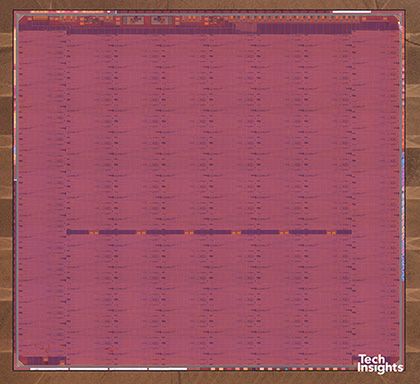

it seems that chinese semiconductor company finally moved to 7nm ( no EUV ) comparable with TSMC and

overtook the Global Foundries with their obsolete 12nm + process

it seems that chinese semiconductor company finally moved to 7nm ( no EUV ) comparable with TSMC and

overtook the Global Foundries with their obsolete 12nm + process